APM 216 HD

- Home

- machines

- Hermetic Press Machines

- APM 216 HD

OVERVIEW

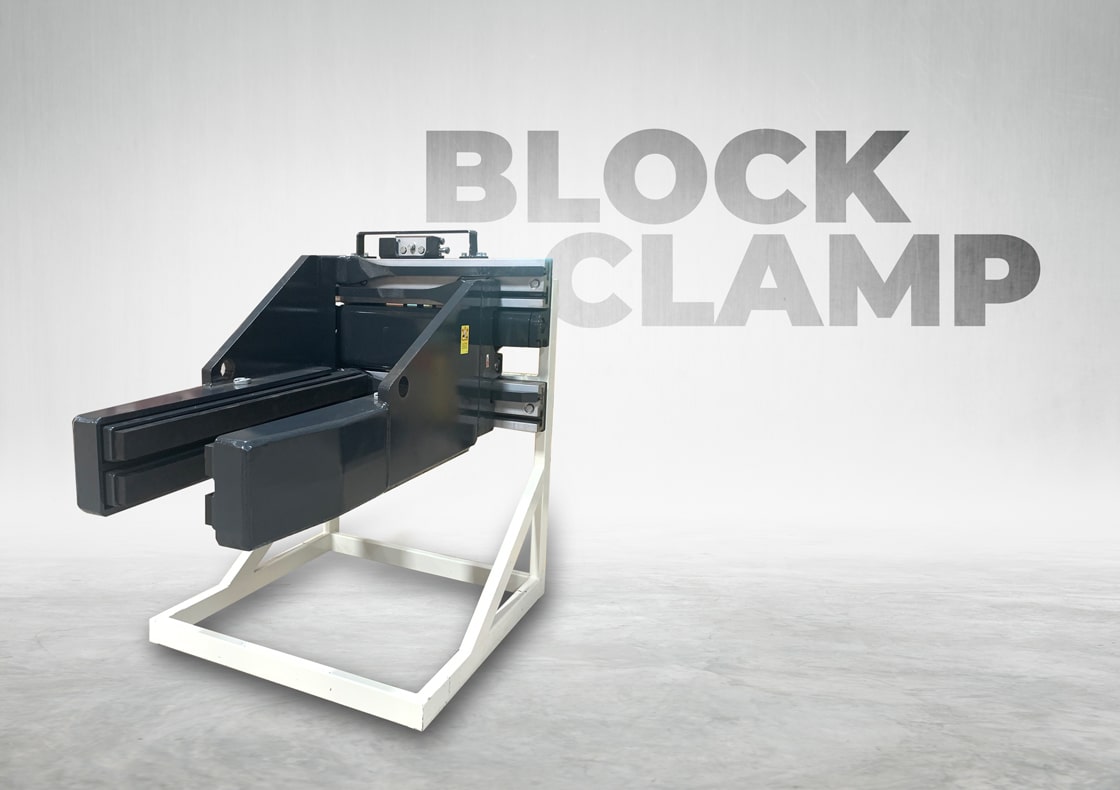

APM 216 HD

Concrete Pavers Making Machine

The Parijatha Two station Rotary Press APM-216HD is more suited for small production facilities or to compliment bigger machines as an auxiliary to produce in smaller quantities.

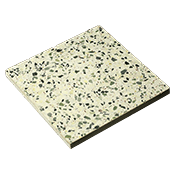

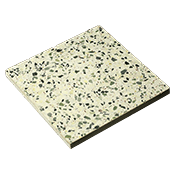

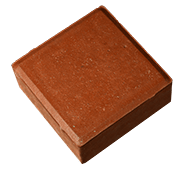

Relatively lower mould cost makes it versatile enough to produce special products. This machine is primarily used to produce Terrazzo Tiles, Slabs, Grooved (Checkered )Tiles, paving blocks and other custom products.

This process involves producing products in Two layers- the face Mix(which is a wet Mix) and the backing layer which is a slightly moist zero slump concrete mix. The face mix is thoroughly vibrated before the backing layer is dosed into the mold. The next stage involves applying very high pressure after which the product is de-molded in the following station and subsequently sent for curing using a range of handling systems.

The product manufactured by this process is characterized by its excellent abrasion resistance, high Transverse Split Strength properties, and low water absorption value which makes it the preferred choice for many applications. Moreover, the products can be SHOT-BLASTED effectively by using a variety of shot sizes to achieve the right surface finish. This gives the product a unique finish that no other manufacturing process can offer.

Max work area

400 x 500 mm

Production capacity

150 Cycles per 8 Hour Shift

Max working pressure

120 tons

Power required

16 HP

Lowest Noise

Less than 60 dB

Sand Blasted Finish

Option available

What can be made?

Hermetic Press is a reliable, simple, and effective procedure of producing High-density Precast Concrete products like Terrazzo Tiles, Paving Blocks and Slabs, Decorative Tiles and Slabs, Grooved Tiles of innumerable designs and combinations, and a range of related products. In addition to this, our unique Vacuum dewatering attachment allows you to produce thinner mono-layer tiles.

RELATED PRODUCTS

APM 316 ED is best paired with

Parijatha Products

Product Catalogue

Download the complete Product Catalogue

Download Catalogue PDF